The Testing Laboratory of material properties (No. 1151) is accredited by the Czech Accreditation Institute (CAI) as per CSN EN ISO/IEC 17025 and it holds a Certificate from General Electric Aircraft Engines.

The Laboratory is a member of the Association of Czech Testing Centers and Laboratories and the largest testing laboratory of the company with unique equipment for testing the properties of construction materials.

Laboratory Profile:

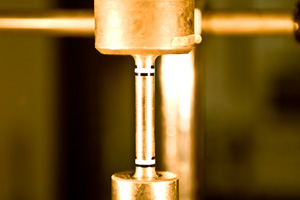

The laboratory conducts experimental research, development, testing and consultancy in the field of increasing reliability, reducing the material costs of structures and components exposed to static and dynamic stress under different conditions.

- determination of basic mechanical and fracture properties according to CSN and foreign standards at normal, low and high temperatures up to 1000 ° C

- detection of low and high cycle fatigue properties of materials at normal, lower and higher temperatures up to 1000 ° C, interaction of fatigue and creep, investigation of damage mechanisms

- thermal fatigue

- assessing the admissibility of defects, detecting crack propagation data and thresholds, assessing residual life of parts with defect

- determination of fatigue strength and life of components, increase of fatigue strength by surface treatments

Laboratory activity:

- pressure vessel tests by internal overpressure - static as well as dynamic tests, experimental evaluation of the static and dynamic bearing power of the pipe sections of a diameter of up to 1200 mm

- technological tests of sheets, wires, ropes, and tubes, sheet deep drawability tests

- technical counseling activity in the area of materials, strength, fatigue, structure, and treatment technology, consultation and supervision of the construction of investment units, and material supplies supervision

- chemical analysis of ferrous materials using an optical-emission analyzer

- optical and scanning electron microscopy, metallographic and fractographic analysis

- tests of corrosion under voltage, corrosion fatigue of hydrogen induced cracking

- determination of fatigue strength and the service life of structural parts and bulky components, certification tests

- quality assessment of weld joints under Czech, foreign and international regulations

- experimental research of the mechanical and fatigue properties of composite materials and components, damaging accumulation assessment

- static and dynamic strain gauges for the evaluation of strength and load-bearing capacity of parts in the laboratory and at the customer

- static and dynamic tests of rail vehicle components (springs, shock absorbers, elastic elements, brake discs, pull rods and impact devices) according to European standards

- performance test of railway axle bearings according to EN 12 082

- fatigue tests by rotation of railway wheels and axles according to European standards

- thermomechanical wheel test according to EN 13 979-1 + A1

- static and dynamic tests of rail welds according to European standards

- static and dynamic tests of building components (ropes, rods, bridge bearings)

- dynamic tests of automotive components (discs, towing equipment) according to EC technical regulations

Contact:

Head of laboratory - Ing. Jan Kec, Ph.D.

Phone: +420 326 509 044

Mobile: +420 728 773 495

E-mail: kec@svum.cz

Dynamic test room

Ing. Armin Delong

Tel: +420 326 509 007

Mobil: +420 724 286 124

Email: delong@svum.cz